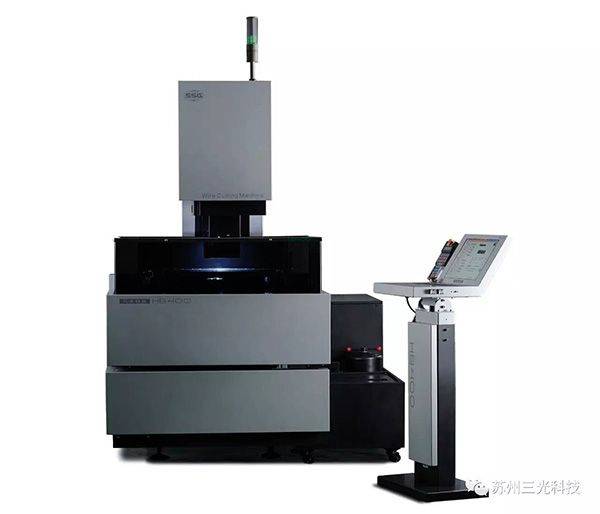

*Linear motor is the "maglev" in machine tool. Because there is no mechanical contact, high responsiveness can be achieved and the ball-screw backlash can be eliminated,the accuracy can be maintained for a very long time.

*Linear motor driven HB400L wire cutting machine tool, five-axis full CNC, performance upgrade again

*Full closed loop drive of linear motor (X, Y axis)

*Z axis numerical control (X, Y, U, V, Z five-axis full CNC control) is realized for the first time.

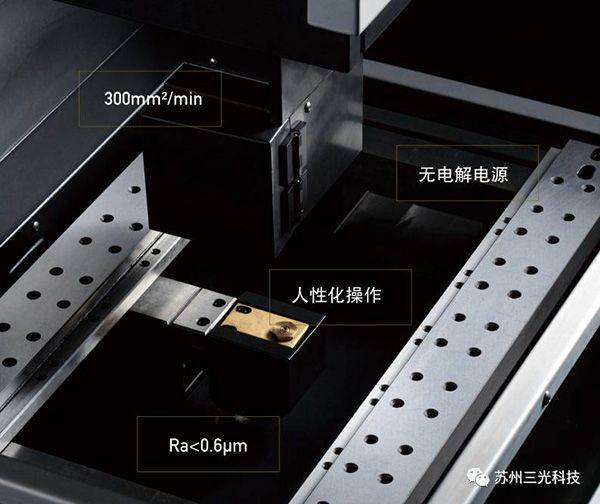

*Original non-electrolytic power supply technology

*Best Roughness Finish: Ra0.6μm

* Max.Cutting speed 300㎜2/min

※HB400L Specifications

Machine body

Worktable stroke(X,Y): 400*300mm

Wire Speed 1.18-11.8m/s

Machine weight 2260/2560㎏

Machine Dimension(L*W) : 2020*1700mm

Max.workpiece height 300mm

Max. Cutting Angle 20o/100mm

Worktable size 580*460mm

Max.workpiece weight 500㎏

Water tank

Filter accuracy 0.01mm

Capacity 130L

Working Methode Filtration System

Pulse Power

Max cutting speed ≥300㎜2/min

Best Surface Finish Ra≤0.6μm

Max. Cutting Currrent 12A

CNC

Hardware Configurations:

Linear Motor, Full closed-loop

and Schneider Inverter

Data Port: USB, LAN

Programming Code: ISO code

Axis Numbers:

5-axis and 4 axis simultaneous control,

pitch compensation realized.

Menu Language :

Chinese/English/English (Inch)

/ Italian/ Korean/Japanese

Aluminum cutting option

Power Supply

Power 380V±10% 50±1HZ

Working temperature 10-35℃

Consumption 1.2KVA

Pneumatic Power

Air pressure 0.5MPa above

Supply flow 30NL/min(ANR)

Air Port 6( Inner diameter)